Suitability targeted for potential future diesel fuels

15 May 2023 – A new no-harm test for additives in fuels is to be developed by OWI Science for Fuels gGmbH and the Chair of Piston Machines and Internal Combustion Engines at the University of Rostock in a joint research project. The increasing use of new climate-friendly biogenic and synthetic fuels and fuel compositions will require a large number of new additives, which in turn will have to be subjected to conscientious testing in accordance with no-harm criteria.

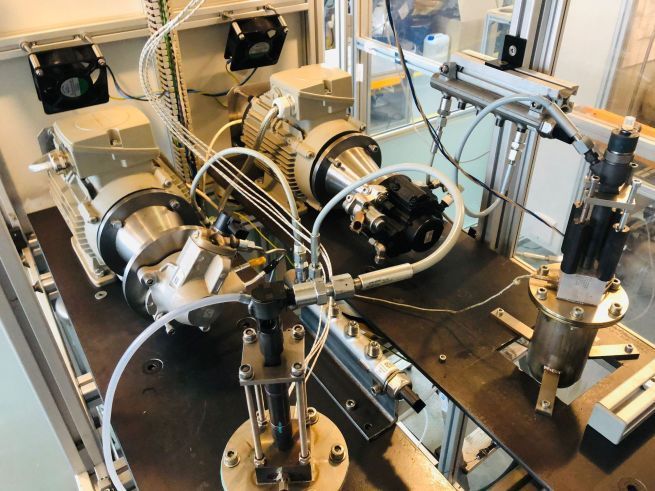

For this purpose, the Diesel Deposit Formation Test (DDFT) and the ENIAK bench test come into question, which the researchers want to evaluate for their suitability as a successor to the XUD-9 test procedure or develop a technically up-to-date no-harm test from both procedures.

Regardless of the effectiveness of fuel additives, it is always necessary to ensure that the additives used do not have any adverse side effects. No-harm tests for additives are always carried out in a comparison between an unadditivated fuel and a fuel mixed with the additive to be tested. The no-harm criteria must be passed by an additive in order for it to be included in the so-called no-harm list. In the industry, this list serves as a guide to the use of additives and, to a certain extent, represents a certificate of harmlessness. To fulfill this function, the test must be as close to the application as possible and as up-to-date as possible.

To this day, XUD-9 diesel engines from the 1980s are used for no-harm testing of additives such as lubricity improvers, flow improvers and antioxidants. “Modern common-rail diesel engines now operate with much more complex injection processes and higher pressures, making them much more susceptible to deposits inside injectors (IDID, Internal Diesel Injector Deposits). However, IDID cannot be mapped at all by the XUD-9 test method still in use today,” explains Sebastian Feldhoff, the project manager on the part of OWI Science for Fuels gGmbH. In addition, the XUD-9 does not correspond to the current state of the art and the procurement of spare parts for the obsolete XUD-9 engine is also becoming increasingly difficult.

“The new test method is to be developed for FAME-free diesel fuels (B0), diesel fuel-FAME blends (B10), as well as a selection of potential future diesel fuel compositions, and will thus also have relevance in the future” explains Sebastian Feldhoff. “At the same time, it must not be too complex and too expensive, for which the Diesel Deposit Formation Test (DDFT) and the ENIAK bench test offer good prerequisites.”

The IGF project 22629 BG of the research association DGMK German Society for Sustainable Energy Carriers, Mobility and Carbon Cycles e.V.– DGMK, Große Elbstraße 131, 22767 Hamburg, was funded through the AiF as part of the program for promoting joint industrial research (IGF) by the German Federal Ministry for Economic Affairs and Climate Action based on a German Federal Parliament resolution.