Hochtemperaturtechnik

Themenfelder

- Industrielle Thermoprozesstechnik

- Blockheizkraftwerke

- Elektrische und hybride Beheizung

- Festoxidbrennstoffzellen (SOFC)

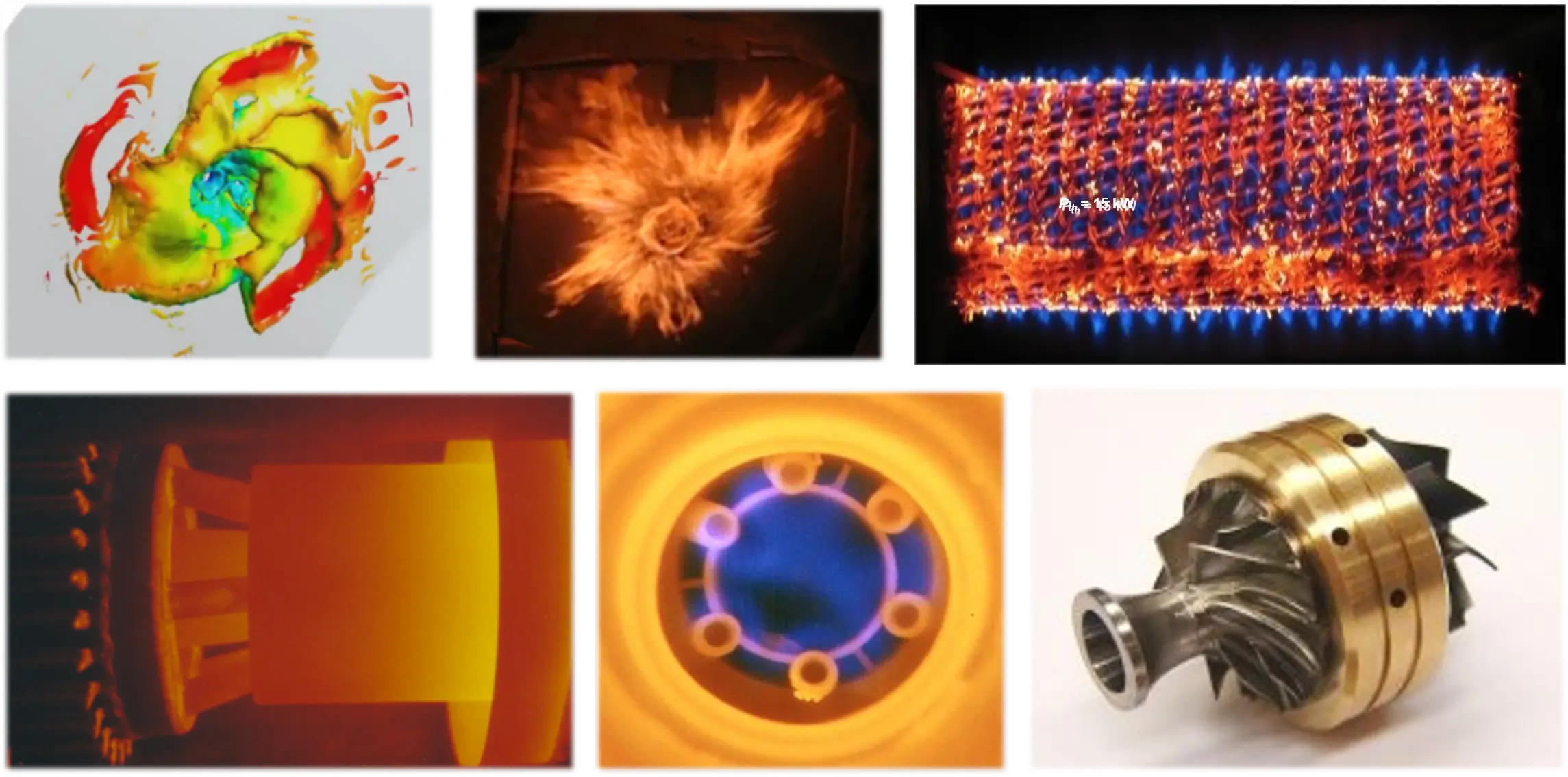

- Verbrennung und Hochtemperaturreaktoren

- Beständigkeit von Hochtemperaturmaterialien

Kompetenzen und Methoden

- Brenner- und Reaktorentwicklung sowie Tests

- Entwicklung von HT-Sensorik

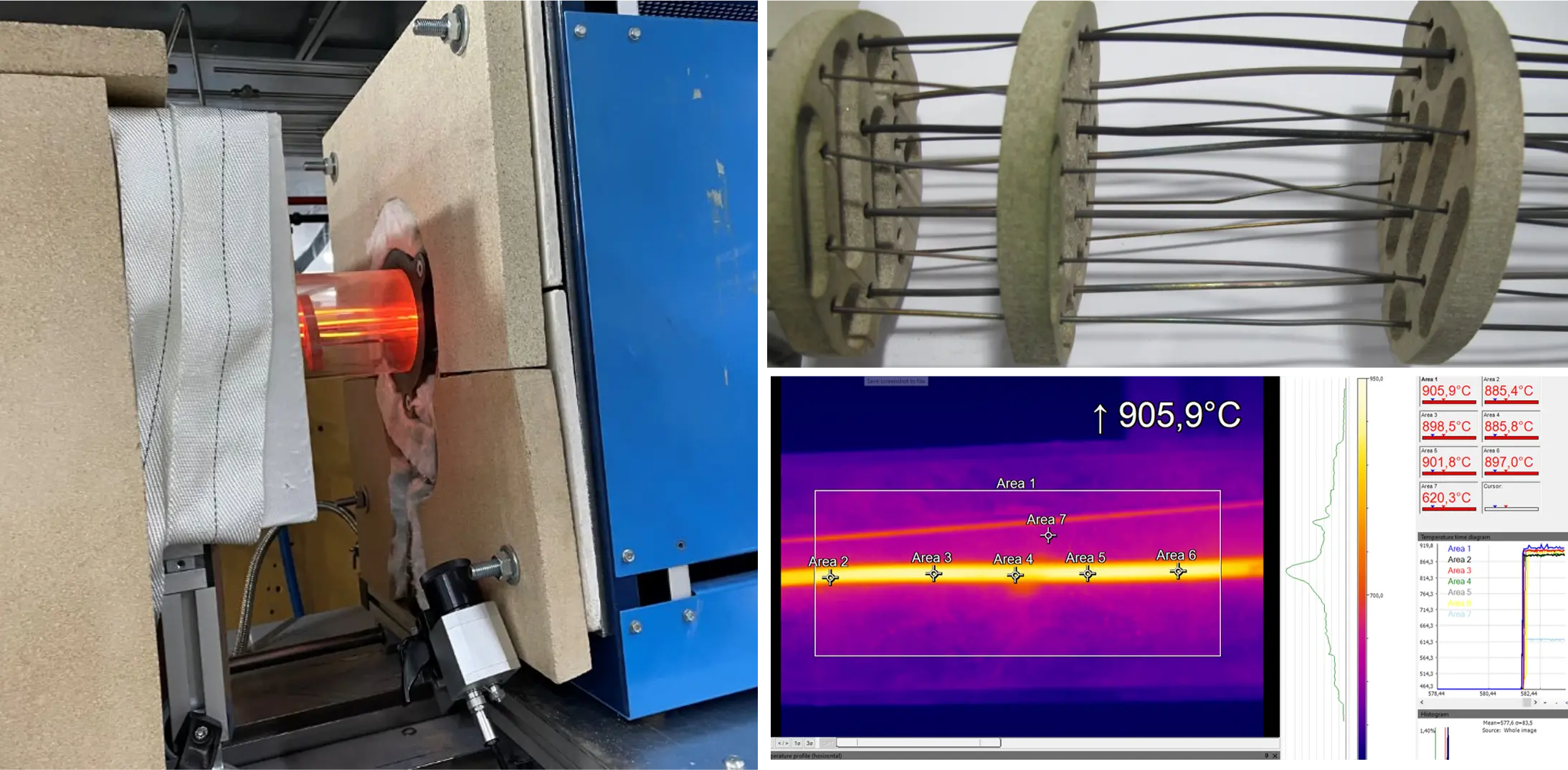

- Materialuntersuchungen ab 500 °C

- Material-Schnellalterung und Langzeittests unter komplexen Bedingungen

- Testen elektrischer Heizelemente

- Modellierung: CFD, FEM, analytisch

Unsere aktuellen Projektthemen

- Ammoniak als Energieträger: Materialkompatibilität und -alterung

- Hybride Industrieofenbeheizung: Materialtechnische Auslegung elektrischer Heizelemente

- Thermoakustische Sensorentwicklung: Erdgas-H2-Flammen im Industriebrenner

- Wärmespeichermaterialien: sensible Wärmespeicherung in der Industrie

Ansprechpartner

Dr.-Ing. Siri Harboe-Minwegen

Teamleiterin Hochtemperaturtechnik