Biogenic fuels can be used flexibly

22 June 2020 – A new type of multi-fuel fuel gas generator has the potential to make more flexible use of the increasing variety of alternative liquid fuels in low-output gas-fired combined heat and power (CHP) plants. Scaling for medium output is possible. For example, fuel gas generators can be used to convert hydrogenated vegetable oils and bioethanol into a hydrogen-rich gas and reduce greenhouse gas emissions in the production of electricity and heat. The multi-fuel fuel gas generator can compensate for the fluctuating chemical-physical properties of different biogenic fuels.

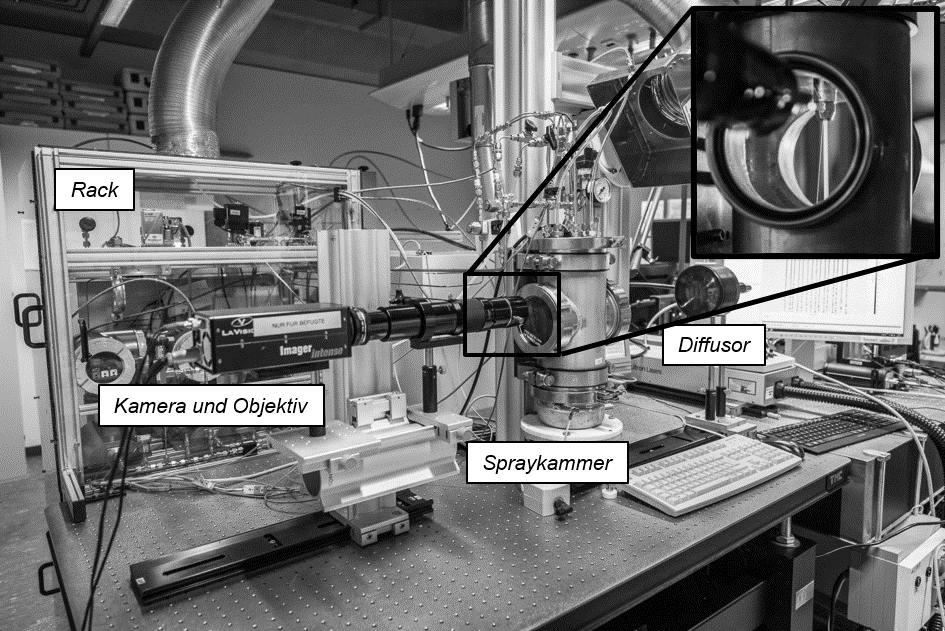

View of the atomizer nozzle test stand and detailed view of nozzle and spray in the spray chamber. Photo: ZBT

Extensive adaptation or conversion work for a change of fuel, for example on the engine technology of CHP units, is not necessary. The multi-fuel fuel gas generator was developed in a joint research project of the Institute for Micro Process Engineering at the Karlsruhe Institute of Technology (KIT), OWI Science for Fuels gGmbH (OWI) and the Center for Fuel Cell Technology (ZBT).

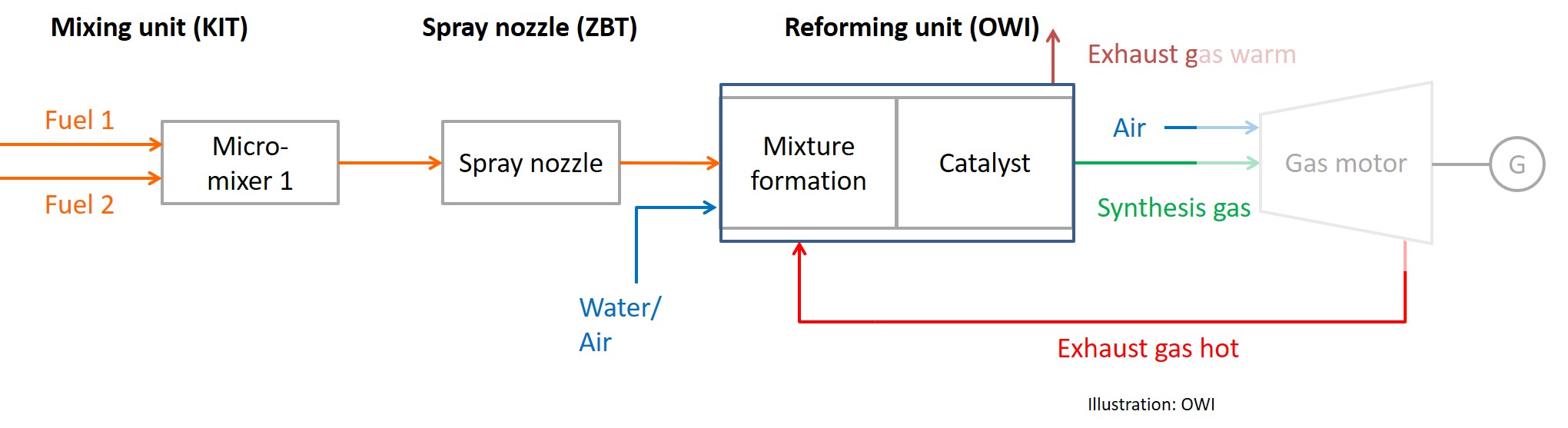

Different liquid biogenic and fossil fuels with varying properties can be used in the fuel gas generator. It consists of a micro mixer, a novel spray nozzle and a reformer unit containing a mixture former and a catalyst. The micromixer (cyclone mixer) developed at KIT processes different fuels to a homogenous mixture. The spray nozzle is a multi-hole nozzle designed by ZBT, which generates a spray usable for the reformer from different fuel mixtures. The reformer developed at the OWI converts the spray into an energy-rich synthesis gas which can be used in the CHP for power and heat generation.

The individual investigations of the project showed that the fuels used in the experiments, rapeseed methyl ester, hydrogenated vegetable oil, sunflower oil, ethanol and fuel oil, could all be used. The compositions of the synthesis gases obtained from the fuels were very similar under comparable boundary conditions. The hydrogen content was consistently around 30% and the carbon monoxide content around 10%. Until the end of the project, the coupled operation of the spray nozzle with the reformer was a challenge. During operation, malfunctions occurred due to blockages of the nozzle bores and the formation of deposits. The development of adapted filter and process concepts to avoid these challenges could be subject of a follow-up project.

The overall system of the fuel gas generator offers CHP plant operators the possibility to use a selection of the currently most cost-effective fuel and to integrate a Least Cost Routing (LCR) into the plant’s operating strategy. In addition, it offers the possibility to increase the electrical efficiency of the plant , as the waste heat from the plant can be used for the reforming process. The economic benefit of the fuel gas generator can increase the economic attractiveness of CHP plants if different biogenic fuels are used.

Functionality of the fuel gas generator

In the fuel gas generator, the fuels are first processed in a micro-mixer to form a homogeneous mixture and then sprayed through an atomizer nozzle into the reformer, where the spray mixes with steam and air. The reformer catalyst then converts this mixture into a hydrogen-rich synthesis gas. The gas drives the engine of the CHP and the connected power generator converts the energy into electricity. Part of the hot engine exhaust gas is fed through the reformer separately from the fuels in the mixture formation and the synthesis gas produced in the catalyst in order to supply the endothermic processes of reforming with heat. In other words, the hot exhaust gas is used for heat exchange and does not come into contact with the process gases. The integration of the heat from the engine exhaust gas makes it possible to upgrade the fuel energetically and increase the electrical efficiency of the CHP system. In CHP operation, the residual heat still present in the exhaust gas after reforming can then be used to prepare hot water.

The IGF project 19168 N of the Research Association “Environmental Technology”, Bliersheimer Str. 58-60, 47229 Duisburg, is funded by the AiF within the framework of the programme for the promotion of joint industrial research and development (IGF) by the Federal Ministry of Economics and Energy on the basis of a resolution of the German Bundestag.