EU research project develops new CHP system for biogenic residuals

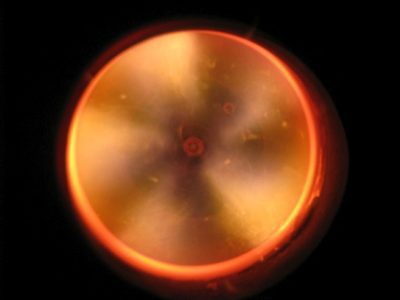

Flame pattern of a combustion of pyrolysis oil (FPBO). Photo: OWI

10 July 2019 – A new EU research project will design a novel small-scale cogeneration engine using biomass to produce heat and electricity, which could mainstream renewables in the heating and cooling sector. The project, called SmartCHP, has been launched today in Brussels by ten partners including European industrial companies, Universities and innovation experts, under the coordination of BTG Biomass Technology Group.

Bert van de Beld, Chief Technology Officer at BTG, said “Currently, the vast majority of cogeneration plants use natural gas and fossil fuels as their primary source. The SmartCHP system will provide a small-scale solution for hospitals, universities, municipal buildings and countless industrial users that would like to use an efficient alternative to fossil sources. With a market potential of 4 billion, and an estimated 85 to 95% less Greenhouse Gas emissions compared to fossil fuels, the installation of the SmartCHP technology in Europe can bring new jobs, more renewables and mitigate climate change.”

The main novelty is the use of fast pyrolysis bio-oil from woody and non-woody biomass in a converted diesel engine, which has been chosen for its high electrical efficiency (more than 40%). The engine will be designed to have high flexibility, meaning that it can easily operate with different loads and produce more electricity or more heat as demand changes. This will be made possible thanks to the integration of a boiler and the use of bio-oil rather than solid biomass. As the SmartCHP system is hybrid, it can also be integrated with variable renewables, such as wind and solar. When the electricity provided by wind and sun is unavailable, the engine starts working on biomass, securing the supply of renewables.

Fast pyrolysis has the advantage of being able to transform difficult-to-handle biomass of different nature – such as verge grass, bark and husks – into a clean and uniform bio-oil, which is easy to store and use for bioenergy. Besides, the new Renewable Energy Directive introduced sustainability criteria concerning biodiversity, emissions and low indirect land use change that will apply to all pyrolysis bio-oil with no exception. This makes sure its production and its use in the project is sustainable.

One of the main challenges of the project is that pyrolysis bio-oil is more corrosive and thick than diesel, contains more water and is therefore more difficult to ignite. Partners of the SmartCHP project will work on modifications to the engine and the ignition system of the bio-oil to overcome this issue. At the end of the project, partners will build a demonstration cogeneration unit capable of running continuously for up to 500 hours in realistic conditions.

In the project, OWI demonstrates the use of FPBO as an alternative fuel in a boiler integrated into the CHP system in addition to the engine to cover peak loads. The boiler generates additional heat when the engine is running at low power, e.g. because the demand for electricity is low or is covered by sources such as wind and solar energy. For this purpose, OWI adapts a standard fuel oil boiler with a capacity of 75 kWth for the combustion of FPBO. In addition, OWI is responsible for integrating the boiler into the catalytic exhaust aftertreatment system and supports the integration of the boiler into the complete SmartCHP prototype.

The SmartCHP project has received funding of 4 million from the European Union´s Horizon 2020 research and innovation programme under grant agreement nº 815259. It started in June 2019 and will run for 4 years. The partners are OWI Oel-Waerme-Institut, Abato Motoren, Exergia Energy and Environmental Consultants, Capax Environmental Services, Greenovate! Europe, Technical University of Eindhoven, Tehag Germany, Denmark Technical University, Dowel Management, under the coordination of BTG Biomass Technology Group.

The SmartCHP project has received funding of 4 million from the European Union´s Horizon 2020 research and innovation programme under grant agreement nº 815259. It started in June 2019 and will run for 4 years. The partners are OWI Oel-Waerme-Institut, Abato Motoren, Exergia Energy and Environmental Consultants, Capax Environmental Services, Greenovate! Europe, Technical University of Eindhoven, Tehag Germany, Denmark Technical University, Dowel Management, under the coordination of BTG Biomass Technology Group.

Project description

SmartCHP – Smart and flexible Heat & Power from Biomass derived liquids for small-scale CHP application