Non-engine test procedure further developed

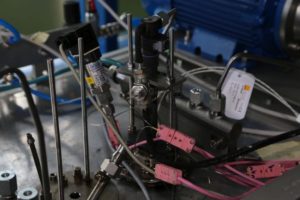

Diesel-Injectors at the test rig. Photo: OWI

21 Oktober 2019 – Within the framework of a research project, the OWI Oel-Waerme-Institut gGmbH and the Institute for Energy Process Engineering and Chemical Engineering (IEC) of the Technische Universität Bergakademie Freiberg have gained important insights into the further development of a non-engine injector test rig including test cycle towards a fast, reliable and cost-effective test procedure for fuels and additives. The test bench is used to investigate and clarify malfunctions of diesel injectors caused by the formation of Internal Diesel Injector Deposits (IDID).

The injector test bench is a realistic replica of a fuel delivery and injection system for common rail diesel vehicles. Individual influences such as the temperature in the area of the injector needle and the injector actuator, the fuel temperature by entering the high-pressure pump and the injector, the injection quantity, frequency and pressure, the fuel and the injector components are investigated. The injected fuel is circulated and reused (loop concept). By reorganizing the method and optimizing the test bench, the test time could be reduced by a third and the required fuel quantity halved from 60 to 30 liters.

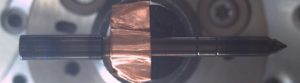

Valve needle of a diesel injector. Photo: OWI

The in-situ degradation of the fuel in the test bench (loop concept) and the selection of suitable operating parameters made it possible to create relevant deposits on injector needles, which led to malfunctions, even without the use of deliberately added critical components. This made it possible to determine the operating conditions under which internal deposits in diesel injectors can form on the test bench. Investigations of these deposits using various analytical methods showed that the deposits generated in the test bench are comparable with deposits from the field with regard to their effects on the injector function. The results of the tests also correspond to the descriptions in the technical literature.

In the future, the research results could contribute to the introduction of the non-engine analysis method developed within the framework of the No-Harm requirement for fuel additives as a test criterion for the formation of deposits under various technical conditions in injection systems for diesel fuels. Already today, diesel injectors can be intentionally contaminated with IDID using this method in order to carry out subsequent engine tests. The test method can also be used to develop or improve additives and fuels.

The IGF project 18575 BG of the research association German Society for Petroleum and Coal Science and Technology e.V. – DGMK, Überseering 40, 22297 Hamburg is funded through the AiF as part of the program for promoting joint industrial research (IGF) by the German Federal Ministry of Economics and Energy based on a German Federal Parliament resolution.

The IGF project 18575 BG of the research association German Society for Petroleum and Coal Science and Technology e.V. – DGMK, Überseering 40, 22297 Hamburg is funded through the AiF as part of the program for promoting joint industrial research (IGF) by the German Federal Ministry of Economics and Energy based on a German Federal Parliament resolution.