Real-time measurement method for the production process

14 March 2022 – Researchers at OWI Science for Fuels gGmbH have identified two real-time measurement methods that are suitable for determining the homogeneity of lubricating greases during their production process. They showed for a lithium soap grease and a urea grease that the methods refractometry and FTIR-ATR spectrometry are suitable for assessing the homogeneity of the thickener structure of these greases that is the state of this structure during the homogenization process. Both methods can be easily integrated into the real-time monitoring of grease production and lead to valid results quickly, i.e. in less than one minute.

The homogenization is a final step of the production process of lubricating greases. In this process a homogeneous distribution of the base oil, the thickener and the additives in the grease is to be achieved by means of mechanically mixing. The random checks currently used to determine the homogeneity of the greases are time-consuming and expensive. Automation of homogenization has not been possible until now because suitable measurement parameters and methods were lacking.

Real-time refractometry and FTIR-ATR spectrometry measurements possible

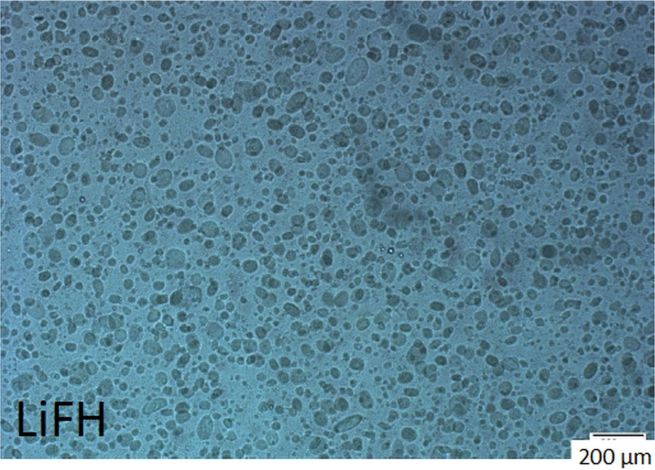

The investigations by OWI showed that the thickener forms a network of fibers both in the lithium soap and the urea grease and that homogenization of the greases leads to a refinement of this thickener structure. Measurement methods based on either the propagation of light waves or sound waves in the sample were tested and evaluated with respect to their potential to quantify grease homogeneity. While measurement methods based on sound waves were not found to be suitable, a correlation between measurement signal and homogeneity of the grease was shown for refractometry, which is the measurement of the refraction of light in the grease sample, and for IR spectrometry, the measurement of the absorption of infrared light. A significantly higher refractive index was measured for homogenized model greases than for the unhomogenized grease. The different degrees of homogenization of fat blends could also be differentiated by the refractive index.

For the investigations with IR spectrometry, an FTIR spectrophotometer was used and the attenuated total reflectance (ATR) measurement setup was chosen. With this measurement method, significant differences in the strength of the absorption bands of the respective thickener were evident between the homogenized greases and the unhomogenized grease for both types of grease.

Comparison of the results of refractometry and FTIR-ATR spectrometry shows that both parameters, the refractive index and the integral area of the thickener band, differentiate homogeneity with comparable sensitivity. The result is that both methods can be used directly in lubricant production, where corresponding methods were not known until now. For the homogenization process, this can be expected to result in a significant reduction in the time required and thus also in the financial outlay.

Supplementary investigations of model greases with extreme-pressure additives showed that a combination of refractometry and FTIR-ATR spectrometry could possibly also provide information about the distribution of the additives in the grease, provided that the additive has a significant influence on the refractive index. However, further investigations are needed to make robust statements on this relationship.

For the practical application of refractometry and FTIR-ATR spectrometry beyond the greases selected in the project, it must be examined in the future whether they can also be applied to assess the homogenization of thickener structures of other types of grease.

The IGF project (20867 N) of the research association DGMK German Society for Sustainable Energy Carriers, Mobility and Carbon Cycles e.V.– DGMK, Große Elbstraße 131, 22767 Hamburg, was funded through the AiF as part of the program for promoting joint industrial research (IGF) by the German Federal Ministry for Economic Affairs and Climate Action based on a German Federal Parliament resolution.