Model development for the purity of cooling liquids

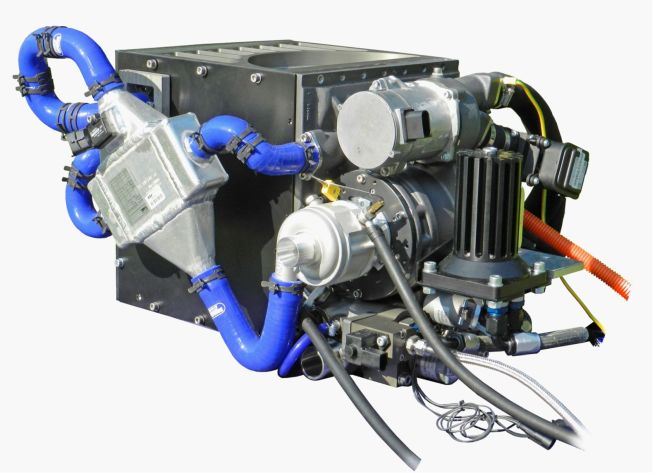

02 November 2022 – Vehicles with electric drives need efficient cooling. The heat generated during operation by fuel cells, battery systems, electric motors and power electronics, must be dissipated to ensure the longevity and safety of the components. This places high demands on the cooling system and the purity and associated low conductivity of the cooling fluids throughout their service life. In a current FVV e.V. research project, OWI Science for Fuels GmbH and RWTH Aachen University are investigating the purification of dielectric cooling fluids for electric drives based on fuel cell systems. Dielectric, i.e. non-conductive, cooling fluids must avoid undesirable effects such as corrosion and electrical short circuits in addition to their cooling properties.

During operation of the cooling system, impurities such as water, metallic particles or ions can occur, which lead to a degradation of the dielectric properties. Therefore, the use of filters or separators in cooling circuits is common. However, their ability to absorb impurities is limited. Thus, when designing a filter or separator, it is important to know what type and amounts of contaminants are expected in a system in order to determine replacement intervals.

To reduce the need for individual time-consuming and cost-intensive tests that have been common practice up to now, OWI Science for Fuels and the Chair of Thermodynamics of Mobile Energy Conversion Systems at RWTH Aachen University are developing a method that can be used to predict the service life of filters and necessary replacement intervals for a defined storage capacity and typical operating conditions. Specifically, the introduction of ions into cooling media for fuel cell systems and their removal by means of ion exchanger filters will be investigated. A model will be developed that can be individually adapted and scaled to different system architectures. The model reduces both the development and testing effort as well as the development times for the design of the cleaning unit.

The knowledge gained about the efficient cooling of electric drives should be universally usable for all cooling circuits of electrical components, in particular for applications with low-temperature proton exchange membrane (PEM) fuel cells, regardless of whether these are used in cars, commercial vehicles, boats, etc.

The research project was initiated by FVV e. V. within the framework of joint industrial research and is financially supported by the German Federal Ministry of Economics and Climate Protection (project number IGF 22397 N). A committee of industry representatives headed by Dr. Michael Harenbrock, Principal Expert Electric Mobility at MANN+HUMMEL GmbH, is supporting the project.

To the project profile