Degradation of lubricating greases: A causal analysis

14 October 2020 – Malfunctions of rolling bearings can lead to the total loss of an entire technical system or to long downtimes. Insufficient lubrication is the cause of rolling bearing failures in about 50 % of cases. In a current research project, the Competence Center Tribology Mannheim (KTM) and OWI Science for Fuels gGmbH (OWI) want to expand the knowledge about the failure mechanisms of rolling bearings with life-time lubrication. In a previous project, they were able to demonstrate that not only the thermal oxidation of the oils contained in the grease, but also the degradation of the thickeners in the grease play an important role in their failure.

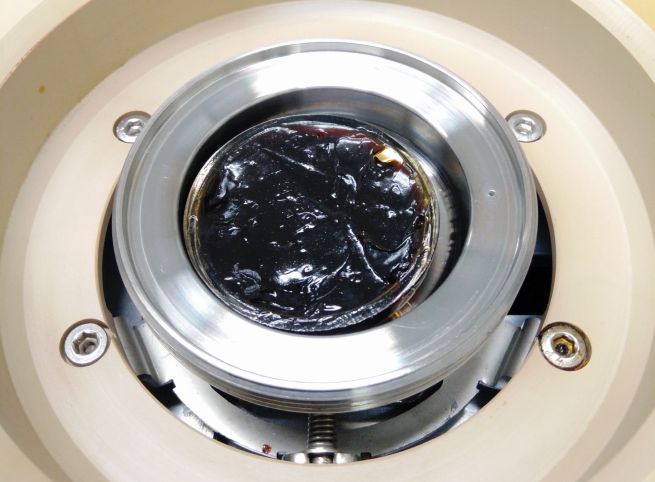

Lubricating greases are semi-fluid lubricants consisting of lubricating oil, thickeners, and additives. The thickener forms a sponge-like structure that encloses the oil. As the grease ages, the thickener’s ability to bind the oil contained in the grease diminishes prematurely. Due to the loss of oil , the rolling bearing loses its lubrication in the long run, resulting in a functional failure and possible system malfunction.

The aim of KTM and OWI is therefore to investigate the change in the thickener structure during aging and mechanical stress. This includes verifying the change and studying its influence on lubrication and thus on the performance and service life of rolling bearings. Using the latest chemical analysis and practical tribological tests, the factors influencing the change will be investigated in detail. The researchers intend to use the resulting findings to develop a screening test strategy for greases. Lubricant screening is not only a part of the actual lubricant characterization at the end customer or market release, but also and above all a part of lubricant development or modification.

The intended screening test strategy should enable a significantly more targeted grease development or grease release testing and thus be more time and cost efficient. Decreasing development costs for lubricating greases also open up opportunities for small and medium-sized companies to offer tailor-made grease formulations for very small quantities or special applications. The new test methodology based on the combination of suitable application-oriented laboratory ageing procedures and targeted rolling bearing tests along with corresponding evaluation methods could in future supplement the complex FE8 and FE9 tests as meaningful preliminary tests.

The IGF project 21251 N of the research association German Society for Petroleum and Coal Science and Technology e.V. – DGMK, Überseering 40, 22297 Hamburg is funded through the AiF as part of the program for promoting joint industrial research (IGF) by the German Federal Ministry of Economics and Energy based on a German Federal Parliament resolution.